Why You Should Choose Professional Commercial Refrigeration Repair in Toronto

Why You Should Choose Professional Commercial Refrigeration Repair in Toronto

Blog Article

Troubleshooting Business Refrigeration Repair: Methods for Quick and Effective Fixes

Comprehending the usual problems that afflict industrial refrigeration systems and having a toolkit of diagnostic techniques at your disposal can make all the distinction in swiftly determining and remedying issues. As we browse with the ins and outs of troubleshooting industrial refrigeration repair, we will reveal the vital techniques for solving issues successfully, making sure that companies can keep optimum air conditioning performance and decrease downtime.

Typical Commercial Refrigeration Problems

Industrial refrigeration systems generally experience a variety of operational concerns that can disrupt their efficiency and efficiency. One widespread issue is inappropriate temperature level control, which can bring about food putridity and waste otherwise promptly addressed. This trouble might come from problems with the thermostat, evaporator follower, or condenser coils, needing thorough inspection to pinpoint the origin. An additional usual concern is insufficient air flow, typically triggered by obstructions in the vents or a malfunctioning fan. Poor airflow can lead to temperature level incongruities within the fridge or freezer, affecting the quality and safety and security of saved items.

Furthermore, cooling agent leaks present a substantial problem as they not just affect the air conditioning capacity of the system but also add to ecological injury. Routine cleansing and upkeep can assist stop this problem and lengthen the life-span of the refrigeration system.

Diagnostic Devices and Strategies

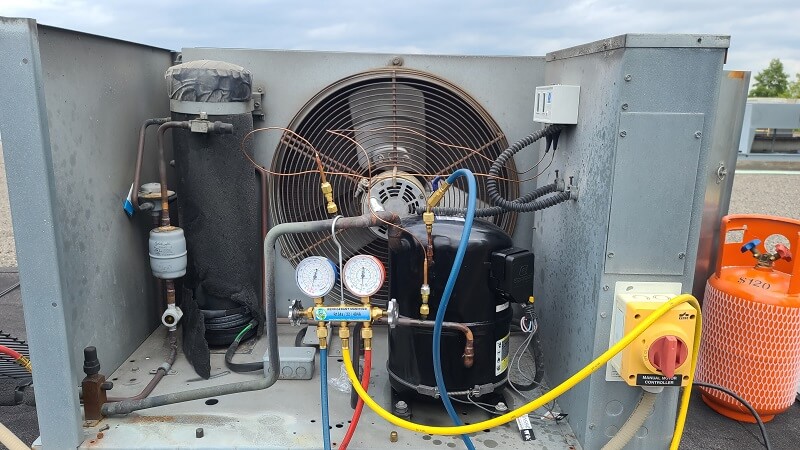

Efficient troubleshooting of commercial refrigeration systems counts greatly on making use of specialized diagnostic devices and strategies to recognize and resolve underlying issues effectively - Toronto commercial refrigerator repair. In addition, leak discovery tools like digital leak detectors or ultraviolet dye kits are important for situating refrigerant leakages that can lead to system inadequacies.

Information loggers can be used to keep track of system efficiency over time and find fads that may suggest reoccuring issues. By combining these diagnostic devices and strategies, specialists can properly troubleshoot industrial refrigeration systems and provide exact and quick repairs, minimizing downtime and making sure optimal system performance.

Quick Repairs for Refrigeration Troubles

When faced with refrigeration troubles, service technicians can apply fast fixes to attend to common issues swiftly and effectively. One common fast fix is examining for a dirty condenser coil, which can cause the system to run inefficiently. Cleaning up the condenser coil routinely can enhance the system's performance and avoid getting too hot. Another quick solution is making certain that the refrigerator is not strained, as overcrowding can limit air movement and bring about temperature inconsistencies. Changing the shelving to permit correct air flow can commonly resolve this concern. Furthermore, inspecting the door seals for any indications of wear or damage and replacing them if essential can help keep the stability of the seal and avoid air leaks. If the refrigeration system is not cooling down visit properly, checking and adjusting the thermostat settings may supply a quick solution before even more comprehensive troubleshooting is needed. By applying these quick fixes, service technicians can resolve common refrigeration problems efficiently and keep industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Applying a positive maintenance routine is important for making certain the longevity and ideal efficiency of industrial refrigeration systems. Normal upkeep not only assists prevent pricey break downs however additionally makes certain that the devices runs effectively, saving energy and decreasing total operating expense. Below are some preventative maintenance ideas to maintain industrial refrigeration systems running efficiently:

Inspect and Replace Filters: Unclean filters can restrict air movement, making the system job more difficult and possibly causing damages. Check and change filters frequently to protect against issues.

Inspect Seals and Gaskets: Leaking seals and gaskets can result in temperature variations and energy wastefulness. Replacing and checking harmed seals can help keep consistent temperatures.

Specialist Support and Services

To keep the ideal performance attained through normal preventative upkeep, seeking professional assistance and services for commercial refrigeration systems is essential. Specialist specialists have the experience and specialized understanding required to identify and address complicated issues successfully. When dealing with tough refrigeration issues, counting on professional assistance can save both money and time in the long run.

Specialist services supply benefits such as accessibility to innovative tools and devices, ensuring that repair work are accomplished successfully. Additionally, professionals are trained to comply with sector regulations and security criteria, reducing the risk of accidents and ensuring compliance with lawful requirements.

Final Thought

Finally, troubleshooting business refrigeration repair needs an organized method to determining common problems, using analysis tools and techniques, executing fast solutions, and prioritizing preventative maintenance. Specialist support and services may be needed for even more complex issues - Toronto commercial refrigerator repair. By following these methods, organizations can guarantee their refrigeration systems operate efficiently and efficiently, lessening downtime and possible losses

Understanding the common problems that torment business refrigeration systems and having a toolkit of analysis techniques at your disposal can make all the distinction in quickly determining and treating problems.Efficient troubleshooting of industrial refrigeration systems depends greatly on using specialized analysis devices and techniques to recognize and deal with underlying issues efficiently. By combining these analysis tools and methods, service technicians can successfully fix industrial refrigeration systems and supply fast and exact repair work, lessening downtime and making sure optimum system efficiency.

By applying these fast solutions, technicians can deal with typical refrigeration problems successfully and maintain business refrigeration systems running efficiently.

In addition, expert support can help expand the life-span of commercial refrigeration systems by recognizing prospective issues prior to they rise.

Report this page